Xanthan gum is valued for enhancing texture, viscosity, and stability in food products. It plays a key role in extending the shelf life of processed foods.

This blog examines the technical mechanisms by which xanthan gum stabilizes and preserves food products, helping manufacturers extend product longevity.

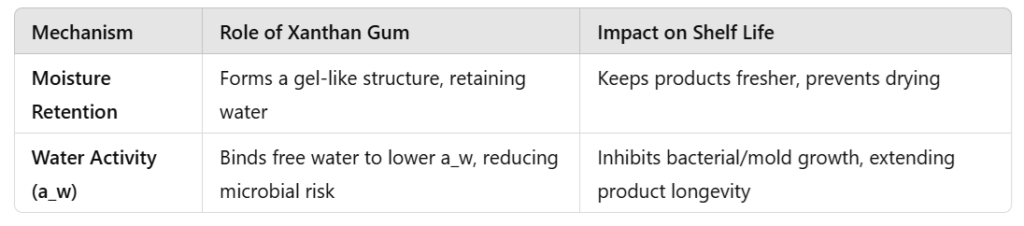

Moisture Retention and Water Activity Control using Xanthan Gum

A critical function of xanthan gum is its ability to bind water, which significantly impacts food shelf life by controlling moisture retention and reducing water activity (a_w).

Lowering water activity slows down microbial growth and enzymatic reactions, both of which are major contributors to food spoilage.

- Moisture retention: It forms a gel-like network that holds water molecules within its structure. This prevents the loss of moisture over time, particularly in baked goods, sauces, and dressings. As a result, products stay fresher for longer.

- Water activity: Foods with lower a_w levels (usually <0.85) are less prone to microbial spoilage. Xanthan gum reduces the a_w of food products by binding free water, lowering the available moisture content for bacterial and mold growth. This results in a longer shelf life, especially in moisture-sensitive foods such as baked goods and confectionery.

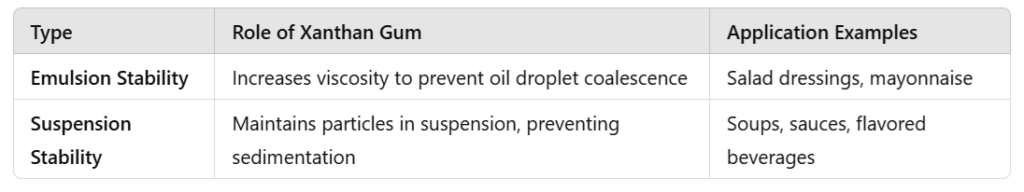

Stabilization of Emulsions and Suspensions

Xanthan gum excels at stabilizing emulsions and suspensions, preventing the separation of phases in products like sauces, salad dressings, and dairy alternatives.

Its ability to increase viscosity without altering taste makes it ideal for products that require consistent texture and stability over time.

- Emulsion stability: It increases the viscosity of the continuous phase in oil-in-water emulsions, preventing the coalescence of oil droplets. This reduces phase separation, extending the shelf life of emulsified products. Studies show that xanthan gum can maintain emulsion stability in salad dressings for over 6 months.

- Suspended particles: In beverages, soups, and sauces containing suspended particles, xanthan gum prevents sedimentation. Its pseudo-plastic nature (shear-thinning) allows the gum to thicken at rest and thin during mixing or consumption, ensuring that particles remain uniformly dispersed throughout the product’s shelf life.

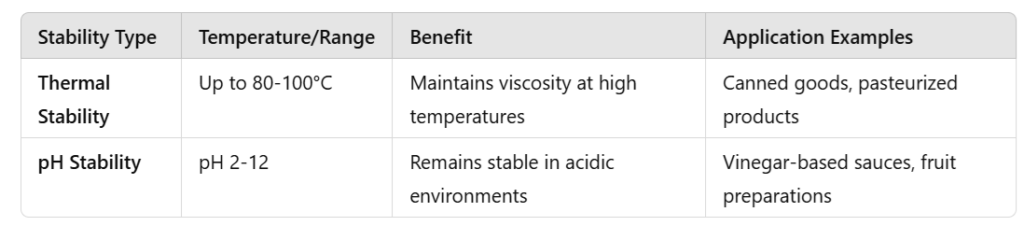

Thermal and pH Stability

One of xanthan gum’s standout features is its high stability under varying thermal and pH conditions, which is crucial for extending shelf life in processed foods that undergo heat treatments or have varying acid levels.

- Heat resistance: It remains effective even at temperatures as high as 80-100°C. This makes it ideal for foods that undergo pasteurization or sterilization processes, such as canned goods and sauces. Its ability to maintain viscosity under heat ensures that product texture and stability remain consistent over time.

- pH stability: Xanthan gum maintains its viscosity in acidic conditions, with a pH tolerance range from 2 to 12. This makes it especially useful for acidic products like fruit preparations, vinegar-based sauces, and beverages. Foods with a pH lower than 4.6, such as fruit juices or pickled products, benefit greatly from xanthan gum’s stabilizing effect.

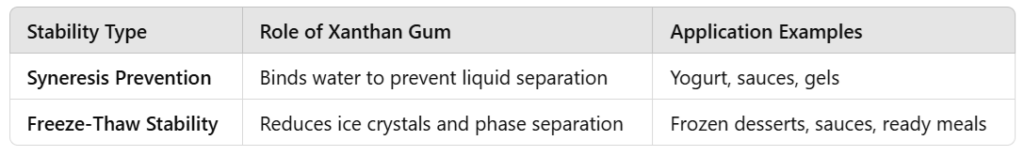

Syneresis Prevention

Syneresis, the separation of liquid from solid or gel components, is a common issue in products like yogurt, sauces, and gels.

Xanthan gum’s water-binding capabilities prevent syneresis, ensuring the product remains cohesive and maintains its intended texture.

- Gel stability: Xanthan gum forms a stable gel network that binds water, preventing liquid from separating from solid or semi-solid foods over time. This is particularly valuable in dairy products like yogurt, where syneresis can lead to an unappealing appearance and texture degradation.

- Freeze-thaw stability: Xanthan gum is resistant to freeze-thaw cycles, preventing the formation of ice crystals and water loss in frozen foods. This enhances the shelf life of frozen desserts, sauces, and ready-to-eat meals by maintaining texture and preventing phase separation.

Conclusion

Xanthan gum’s multifunctional properties—moisture retention, emulsion stabilization, temperature/pH tolerance, and prevention of syneresis—are crucial for extending the shelf life of processed foods.

As the demand for longer-lasting, high-quality processed foods continues to rise, xanthan gum remains a critical tool in food formulation strategies.

Its ability to maintain texture, reduce water activity, and stabilize emulsions across a variety of conditions makes it an invaluable ingredient for food manufacturers aiming to enhance product longevity.